Digital manufacturing is the shift from traditional, labor-heavy processes to a system where data, machines, and people work in sync. At its heart, it’s the use of digital tools to design, test, and produce physical products more efficiently. The difference lies in integration—design models connect directly to production equipment, and performance data feeds back into design. This approach doesn’t replace human expertise; it supports it by streamlining workflows and enabling smarter decisions. It’s about creating a continuous, connected production cycle.

Understanding Digital Manufacturing

Digital manufacturing links engineering, production, and IT into one coordinated system. Instead of passing files from one department to another, all stages are tied together through a shared digital thread. This creates a single source of truth, where every decision is guided by accurate, up-to-date information. The result is improved communication, shorter cycles, and fewer costly mistakes.

The process starts with digital design. Engineers build models using CAD software, but those files are now dynamic. They connect to simulation tools that evaluate stress points, thermal effects, and durability before production begins. Engineers can try out dozens of variations in a matter of hours. That cuts down on wasted prototypes and accelerates innovation.

Once designs are finalized, digital planning tools manage workflow. These systems don’t just show timelines—they adapt to conditions in real time. If demand spikes, schedules adjust automatically. If one machine goes down, another takes over, guided by the same data set. Supply chain issues can be anticipated early, preventing production delays that once seemed unavoidable.

When it comes to making the product, automation plays a large role. Machines are networked, sensors capture key metrics, and inspection happens as parts are produced rather than afterward. This means defects are caught instantly, not weeks later. Operators monitor performance on dashboards that show temperature, speed, or material usage in clear terms. With that transparency, they can act quickly to correct issues and prevent downtime.

Key Technologies Behind Digital Manufacturing

The system depends on several core technologies. IoT is foundational, with connected devices constantly exchanging information. A sensor detecting unusual vibration in a motor can send a signal that triggers maintenance before failure occurs. This type of communication keeps production smooth.

Digital twins add another layer. A digital twin mirrors the behavior of a machine or process, updated with live data. If a piece of equipment shows signs of wear, its twin reflects those changes, letting engineers model how long it will last or when repairs should happen. This foresight saves money and extends asset life.

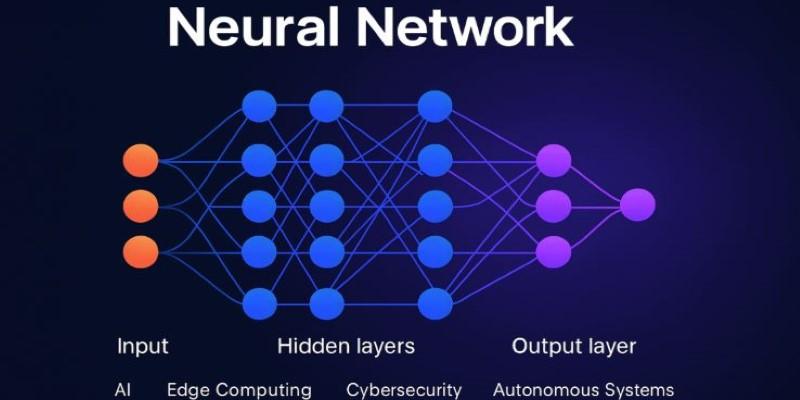

Artificial intelligence makes sense of the growing flood of data. Algorithms detect patterns that no human could process quickly enough. AI might spot that a certain material batch performs better under specific humidity levels, or that a design could be improved with a slight change in dimensions. Machine learning improves accuracy over time, offering more reliable predictions as it absorbs new information.

Cloud computing ties all of this together by storing and processing data across distributed systems. Teams can collaborate from different sites, reviewing the same dashboards and simulations without delay. This accessibility reduces silos and ensures everyone is aligned. For small businesses, the cloud makes advanced tools available without the cost of building a large IT infrastructure.

Additive manufacturing, also known as 3D printing, supports agility. Instead of waiting for molds or tooling, manufacturers can print parts directly from a digital file. This reduces setup times and allows for unique or customized parts to be produced without the overhead of traditional methods. It’s particularly useful for short runs and experimental designs.

Benefits and Real-World Impact

The benefits go far beyond the factory floor. Digital manufacturing brings speed by reducing the gap between design and production. A product iteration that once required months can now be ready in weeks or days. Rapid adaptation becomes possible in industries where demand shifts quickly.

Transparency is another advantage. With access to the same data, decision-making improves across the board. Quality checks happen earlier, miscommunication declines, and every stage is documented. This reduces errors and builds trust with clients and partners.

Sustainability is improved as well. Processes are monitored closely, waste is reduced, and materials are tracked for efficiency, while predictive maintenance prevents unnecessary replacements. Energy consumption is easier to control. These practices save money, support environmental standards, and show responsibility.

Workforces are shifting with these changes. While repetitive manual tasks are automated, new responsibilities arise around monitoring, troubleshooting, and data interpretation. Workers need training in software and analytics, making manufacturing careers more technologically oriented. This attracts wider talent and supports long-term growth.

Small businesses are not excluded. Affordable sensors, scalable cloud platforms, and modular robotics give even small workshops efficiencies of larger plants. This opens doors to innovation and keeps local production competitive with overseas operations. It creates opportunities where customization or quick turnaround is valuable.

The Future of Digital Manufacturing

Digital manufacturing is moving beyond factory optimization to become the backbone of supply networks. Each stage, from raw materials to distribution, is linked through shared data systems, allowing manufacturers, suppliers, and retailers to anticipate changes together rather than react individually.

Mass customization is a growing trend. Instead of standard products in bulk, companies can offer tailored items at little added cost. Customers adjust designs online, and those specifications flow directly into production. This level of personalization gives companies a new competitive edge.

Resilience is another outcome. When disruptions occur—whether from shortages or global events—connected systems respond quickly. Factories can shift schedules, source alternatives, or adjust designs to keep production going. Companies adopting digital manufacturing are better prepared for uncertainty.

Challenges remain. Integrating new systems into older infrastructure requires investment. Cybersecurity is a concern as machines and data become more connected. Standards must evolve so platforms work together smoothly. Yet as the technology matures, solutions are emerging alongside the benefits.

Conclusion

Digital manufacturing is more than a technology shift—it’s a new way of creating products. By connecting design, data, and production, it eliminates barriers and speeds up processes while reducing errors. Machines, people, and information work in a continuous feedback loop that drives constant improvement. The result is higher quality, faster delivery, and greater sustainability. From small workshops to global factories, digital manufacturing is transforming how products are built and delivered.